Bulletproof glass is a special type of laminated glass, a composite material obtained by special processing of glass (or Plexiglas) and tough PVB/polycarbonate fiber thermoplastic (LEXAN PC RESIN). It usually has good light transmission and has the ability to defend against weapons.

Bulletproof glass work principle is that it can transform the kinetic energy of the bullet impact into the elastic potential energy of the glass and the surface energy of the fragments. On impact, the front layer of glass is designed to absorb the initial impact energy of the bullet through fragmentation, allowing subsequent layers of glass and PVB to absorb lower levels of shock waves. Bullet resistant glass is not damaged by penetration after being subjected to high-velocity, high-pressure fire from a warhead.

Factors affecting the performance of bulletproof glass include the type of material, thickness, number of layers, treatment, dimensions, installation method, and type of bullet (lead-cored or steel-cored).

Bullet resistant glass is manufactured in a range of thicknesses and compositions to meet a number of international safety standards. Bullet resistant glass standards are European BS EN 1063 and American UL752 and NIJ 0108.01, Chinese GA165-2016 . These technical performance specifications require a certain number of test samples that can withstand the impact of a series of bullets fired at a specified speed and from a specified distance. All samples must prevent the bullets from penetrating from the attack side to the safety side to be acceptable.

Bulletproof Glass Types

The following DG ballistic glass products can also be tested to BS EN 1063, NIJ0108.01 and UL752.

| Glass Thickness (mm) +/-2 | Type of Weapon | Calibre of Weapon | Class Threat Level |

| 20-22mm | Hand Gun | 22 LR,38 Special | EN 1063 BR1,NIJ I |

| 25-28mm | Hand Gun | 9mm Luger | EN 1063 BR2 |

| 30-33mm | Hand Gun | .357 Magnum | EN 1063 BR3,NIJ II,UL 2 |

| 35mm-39mm | Hand Gun | .44 Rem Magnum | EN 1063 BR4,NIJ III,UL 3 |

| 39mm | AK Rifle | 5.56 x 45 | EN 1063 BR5,NIJ III,UL 4,STANAG4569 I |

| 52mm | AP Rifle | 7.62 x 51 | EN 1063 BR6,NIJ IV,STANAG4569 II |

| 68-70mm | Rifle | 7.62×51 | EN 1063 BR6,NIJ IV,UL5 |

| 76-80mm | Sniper Rifle,ect | 12.7mm Armor-Piercing, Incendiary | Impact speed:493m/s,distance:30 meters |

| 90-95mm | Sniper Rifle,ect | 12.7mm Armor-Piercing, Incendiary | Impact speed:722m/s,distance:30 meters |

| 104mm | 12.7mm Machine | Armor-Piercing | STANAG4569 III |

Please email: [email protected] or call + 86 18080478893 (whatsapp) so we can discuss your specific requirements,providing you with better service.

How to choose bulletproof glass

9mm Luger – EN 1063 BR2, similar to NIJ 0108.01 IIA

9mm Luger – EN 1063 BR2, similar to NIJ 0108.01 IIA

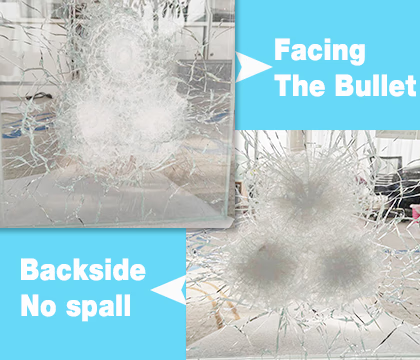

Bulletproof glass Spall Allowed And No Spall (NS)

The requirements for spall allowed/no spall are part of the European standard BS EN 1063 and the Chinese GA165-2016. Spall means the material ejected from the back of the glass when the attacked surface of the bulletproof glass is hit by a ballistic.

Spall allowed bulletproof glass is typically all-glass construction and is only appropriate when personnel are not in close proximity. Spall does not mean ballistic glass is ineffective, as long as the bullet or any bullet fragments do not penetrate to the safe side .

When the bulletproof glass is shot by a ballistic, there is no spall or only slight spall of dust on the back, which is safer and provides better protection for personnel.

ultra-clear (low iron) / ordinary bulletproof glass comparison

Standard or ordinary float glass contains iron, which makes it appear green. The green color does not appear obvious in a single layer of 4 mm or 6 mm glass window. When multiple layers of glass up to 12 mm thick are laminated together to create bulletproof or attack resistant glass, the green color of the glass is more obvious to the naked eye.

To overcome or solve this problem, we can choose using low-iron glass as the substrate. Low-iron glass has a lower iron content than ordinary glass. It is more transparent than ordinary glass and has better stability, allowing to laminate multiple layers and maintain the transparency of the glass, thereby increasing the transparency of light, and there is no visible green color on the glass window or glass door.

Ballistic Technical Specifications

UL752 Standard for Bullet-Resisting Equipment

EN 1063 Glass in building -Security glazing -Testing and classification of resistance against bullet attack

BS 5051 Bullet-resistant glazing – Part 1: for interior use- Part 2: for Exterior use

NIJ 0108.01 US National Institute of Justice Standard-Test and Certification for Ballistic Resistant Materials

EN 1522/3 Windows, doors, shutters and blinds – Bullet resistance – Requirements and classification /Test method

Bulletproof/Bullet Resistant Products Series

Bullet Resistant Window Exterior / Interior Bullet Resistant Window For Residence,Office,Bank,ect.

Bullet Resistant Door Exterior / Interior Bullet Resistant Door For Residence,Office,Bank,ect.

Bullet Resistant Guard Booth Can be used for government, large corporations, companies, banks, and other security booth

Car Bullet Resistant Glass Window (with curvature) Suitable for Toyota, Mercedes-Benz, BMW, Hummer, Ford, Chevrolet, Jeep, Rolls-Royce and many other vehicles